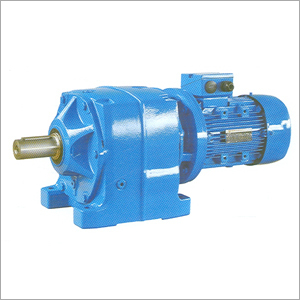

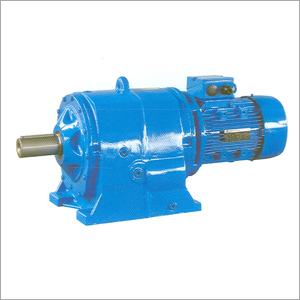

Inline Helical Geared Motor

Inline Helical Geared Motor Specification

- Bearing Type

- Heavy Duty Ball Bearing

- Motor Type

- Inline Helical Geared Motor

- Horse Power

- 0.12 HP to 60 HP

- Sealed Type

- Totally Enclosed Fan Cooled (TEFC)

- Rated Frequency

- 50/60 Hz

- Current Type

- AC

- Voltage

- 380V/415V

- Torque

- Up to 10000 Nm

- Ambient Temperature

- -20C to +50C

- Starting Type

- Direct On Line

- Rated Voltage

- 380V/415V

- Power Rating

- 0.09 kW to 45 kW

- Noise Level

- Low (<70 dB)

- Cooling Method

- Fan Cooled

- Poles Number

- 2/4/6/8

- Efficacy

- IE2/IE3

- Pressure

- Atmospheric

- Features

- High torque, compact design, energy efficient, robust construction

- Product Type

- Inline Helical Geared Motor

- Output Power

- 0.09 kW to 45 kW

- Frequency (MHz)

- 50/60 Hz

- Protect Feature

- IP55

- Phase

- Three Phase

- Speed

- Up to 200 rpm

- Power

- 0.09 kW to 45 kW

- Color

- Blue/Grey

- Dimension (L*W*H)

- Customized

- Weight

- Up to 350 kg

- Shaft Diameter

- Custom/Standard

- Mounting Type

- Foot/Flange

- IP Rating

- IP55

- Insulation Class

- F/Class H

- Gearbox Housing

- Cast Iron/Aluminum

- Output Shaft Type

- Solid/Hollow

- Vibration Level

- Low

- Service Factor

- 1.0 to 1.5

- Transmission Efficiency

- Above 95%

- Thermal Protection

- Built-in

- Lubrication

- Synthetic oil (lifetime fill)

- Mounting Position

- Horizontal/Vertical

- Gear Material

- High-grade alloy steel

- Overload Capacity

- Up to 200%

- Number of Stages

- Single, Double, Triple

Inline Helical Geared Motor Trade Information

- Payment Terms

- Cheque

- Supply Ability

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Inline Helical Geared Motor

Backed with a team of experienced professionals, we are providing a wide range of Inline Helical Geared Motor. Offered geared motor finds applications in material handling, cranes and hoists, textile machines, elevators, packaging machines and sheet metal fabrication. This motor has very low emission operation as compared to combustion engines and hydraulic or pneumatic drives. Robust and easy maintenance, we offer this Inline Helical Geared Motor at industry leading price to the clients.

Features:

-

High load carrying capacities

-

Increased efficiency over worm units

-

Quiet running

-

Energy efficient

Superior Gear Materials and Housing

Designed using high-grade alloy steel gears and reinforced with cast iron or aluminum housings, these geared motors guarantee durability and long-lasting performance even under demanding conditions. This construction also helps maintain low vibration and noise levels for safer, quieter operation.

High Transmission Efficiency and Energy Savings

Boasting a transmission efficiency above 95% and IE2/IE3 energy ratings, the Inline Helical Geared Motor reduces energy consumption and operational costs. Its synthetic oil lubrication ensures smooth movement and minimal maintenance over its lifetime, adding convenience for users.

Versatile Applications and Mounting Options

Available for both horizontal and vertical mounting positions, these motors suit a wide range of industrial settings. With customizable shaft diameters and mounting styles (foot/flange), as well as flexible power and torque specifications, they adapt easily to diverse application requirements.

FAQs of Inline Helical Geared Motor:

Q: How does the Inline Helical Geared Motor maintain high efficiency during operation?

A: The motor achieves transmission efficiency above 95% through precision-machined high-grade alloy steel gears, along with synthetic oil lubrication that reduces friction. Its robust housing and advanced insulation further minimize energy loss, ensuring consistent and efficient performance.Q: What applications are best suited for this type of geared motor?

A: The Inline Helical Geared Motor is ideal for conveyors, material handling systems, packaging machinery, and other industrial automation tasks requiring consistent torque, compact design, and energy efficiency. Its versatile mounting options and wide power range allow use in various industries.Q: When should maintenance be performed on the geared motor?

A: Due to its lifetime synthetic oil fill and durable construction, regular lubrication maintenance is not required. However, periodic inspections for general wear and checks on vibration and noise levels are recommended to ensure peak performance and longevity.Q: Where can the motor be installed in terms of environmental conditions?

A: Designed to operate in ambient temperatures ranging from -20C to +50C, the motor is well-suited for most industrial atmospheres in India. The IP55 protection rating and totally enclosed fan cooled (TEFC) design make it suitable for dusty or humid environments.Q: What benefits does built-in thermal protection offer?

A: Built-in thermal protection helps prevent overheating by monitoring the motors operating temperature. This feature extends the service life, reduces downtime, and safeguards the equipment during intensive applications or unexpected overload scenarios.Q: How does the motor handle overload conditions?

A: The geared motor supports overload capacities up to 200%, providing reliable performance during brief spikes in demand. Heavy-duty ball bearings, solid construction, and advanced cooling methods contribute to its ability to handle such stress without compromising operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Geared Motors Category

Stephan Geared Motor

Minimum Order Quantity : 1 Unit

Protect Feature : Totally Enclosed

Cooling Method : Surface Cooling

Poles Number : Other, 4 Pole

Noise Level : <65 dB

Weight : 22 kg

Hollow Shaft Geared Motor

Minimum Order Quantity : 1 Unit

Protect Feature : Other, IP55 Protected

Cooling Method : Fan Cooled

Poles Number : Other, 4 Poles

Noise Level : <65 dB

Weight : 18 kg

Shaft Mounted Helical Geared Motor

Minimum Order Quantity : 50 Units

Protect Feature : Other, IP55

Cooling Method : Surface Cooling (TEFC)

Poles Number : Other, 2, 4, 6

Noise Level : Low Noise Operation

Weight : 15 kg to 350 kg

Stephan Helical Geared Motors

Protect Feature : Other, Totally Enclosed Fan Cooled (TEFC)

Cooling Method : TEFC

Poles Number : Other, 2, 4, 6, 8 Poles

Noise Level : Low noise operation

Weight : Varies as per model

Send Inquiry

Send Inquiry