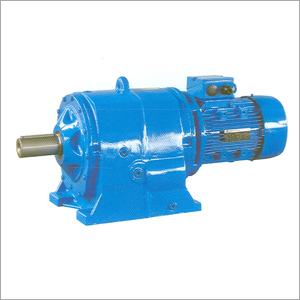

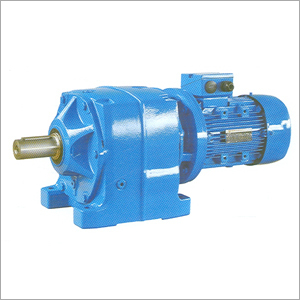

Hollow Shaft Geared Motor

Hollow Shaft Geared Motor Specification

- Standard

- IS 325/IS 1231

- Noise Level

- <65 dB

- Poles Number

- 4 Poles

- Bearing Type

- Heavy Duty Ball Bearing

- Voltage

- 415 V

- Starting Type

- DOL

- Motor Type

- Induction Geared Motor

- Horse Power

- 1 HP

- Current Type

- AC

- Cooling Method

- Fan Cooled

- Pressure

- Standard Atmospheric

- Features

- Compact Design, Maintenance Free

- Sealed Type

- Totally Enclosed Fan Cooled (TEFC)

- Power Rating

- 0.75 kW

- Efficacy

- IE2 High Efficiency

- Torque

- High Torque Output

- Rated Frequency

- 50 Hz

- Ambient Temperature

- -20C to 50C

- Rated Voltage

- 415 V

- Product Type

- Hollow Shaft Geared Motor

- Output Power

- 0.75 kW

- Frequency (MHz)

- 50 Hz

- Protect Feature

- IP55 Protected

- Phase

- Three Phase

- Speed

- 1440 rpm

- Power

- 0.75 kW

- Color

- Grey

- Dimension (L*W*H)

- 300 x 180 x 180 mm

- Weight

- 18 kg

- Shaft Diameter

- 28 mm

- Mounting Type

- Hollow Shaft Mount

- IP Rating

- IP55

- Enclosure

- Cast Iron Body

- Application

- Conveyor systems, Material Handling, Industrial Machinery

- Lubrication

- Grease For Life

- Insulation Class

- F Class

- Flange Type

- Standard B5

- Service Factor

- 1.15

- Gear Ratio

- Available from 5:1 to 60:1

- Duty Cycle

- S1 Continuous

Hollow Shaft Geared Motor Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Hollow Shaft Geared Motor

With the aim of delivering quality products, we trade and supply a wide range of Hollow Shaft Geared Motor. It is used where electric drive with high torques is needed for plant and machinery. The motor is examined strictly under the guidance of our experts on different parameters like maintenance, functionality and efficiency. We provide this, Hollow Shaft Geared Motor of the highest quality with focus on flexible solutions, reliability and client satisfaction.

Features:

- Anti corrosive

- Abrasion resistant

- High operational fluency

Specification

| Range | Power range from 0.35 KW to 70 KW Output Speed from 3.2 to 233 RPM |

| Sizes | Available in 11 sizes |

| Type | Helical Bevel Helical |

| Applications | Conveyors, Agitators, Pumps, Mixers, Ball Mills, Cranes, Crushers |

| Industries | Chemical, Pharma, Packaging, Food Processing, Plastic, Paper etc. |

Versatile Gear Ratios and High Torque

This geared motor offers a wide selection of gear ratios from 5:1 to 60:1, making it adaptable to various industrial needs. Its design enables high torque output, efficiently powering heavy-duty conveyors, material handling systems, and other complex machinery requiring precise, continuous rotation.

Robust Build and Maintenance-Free Operation

The cast iron construction and heavy-duty ball bearings ensure durability even under challenging conditions. The Grease for Life lubrication system, along with a totally enclosed fan-cooled design, makes the motor virtually maintenance free, reducing operational downtime and associated costs.

Superior Protection and Efficiency

Equipped with an IP55 protection feature and F Class insulation, this motor withstands dust, moisture, and high temperatures ranging from -20C to 50C. Its IE2 rating signifies high energy efficiency, which helps reduce running costs while meeting industrial performance standards.

FAQs of Hollow Shaft Geared Motor:

Q: How is the Hollow Shaft Geared Motor typically installed in industrial setups?

A: The motor is installed using a standard B5 flange and hollow shaft mount, making it compatible with most conveyor systems and machinery. Its compact dimensions simplify integration into existing equipment, and the 28 mm shaft diameter suits a variety of mounting requirements.Q: What types of applications benefit most from this geared motor?

A: This motor is best suited for conveyor systems, material handling machinery, and various types of industrial equipment that require continuous (S1 duty) operation with high torque and consistent speed control.Q: When should the grease lubrication system be serviced or checked?

A: The motor features a Grease for Life lubrication system, eliminating the need for routine greasing or maintenance. This ensures long-term operation without frequent downtime for lubrication checks.Q: Where can this geared motor operate effectively?

A: It is designed for use in industrial settings across India, operating efficiently in environments with ambient temperatures ranging from -20C to 50C and under standard atmospheric pressures. Its IP55 rating allows safe usage in areas exposed to dust and moisture.Q: What is the process to select the correct gear ratio for my application?

A: Choosing the right gear ratio depends on the required speed and torque for your application. Assess your systems load, speed requirements, and desired output, then select a ratio between 5:1 and 60:1 that best matches your needs for optimal performance.Q: How does the motors high efficiency benefit my operation?

A: With an IE2 efficiency rating, this motor reduces energy consumption, thereby lowering electricity costs. Its ability to deliver high torque without drawing excessive power makes it environmentally and economically advantageous for continuous industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Geared Motors Category

Stephan Geared Motor

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Color : Blue

Features : Robust Construction, Low Noise, MaintenanceFree

Phase : Three Phase

Efficacy : IE2

Co Axial Helical Geared Motor

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Color : Blue

Features : High efficiency, Robust construction, Low noise, Maintenance free design

Phase : Three Phase

Efficacy : IE2 / IE3

Inline Helical Geared Motor

Frequency (MHz) : 50/60 Hz

Color : Blue/Grey

Features : High torque, compact design, energy efficient, robust construction

Phase : Three Phase

Efficacy : IE2/IE3

Stephan Helical Geared Motors

Frequency (MHz) : 50/60 Hz

Color : Blue/Grey

Features : Robust construction, Low maintenance

Phase : Three Phase

Efficacy : High efficiency

Send Inquiry

Send Inquiry