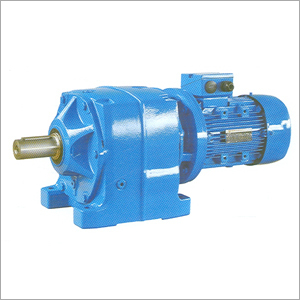

Shaft Mounted Helical Geared Motor

Shaft Mounted Helical Geared Motor Specification

- Rated Frequency

- 50 Hz

- Current Type

- AC

- Bearing Type

- Heavy Duty Ball or Roller Bearing

- Torque

- Upto 12000 Nm

- Poles Number

- 2, 4, 6

- Motor Type

- Shaft Mounted Helical Geared Motor

- Rated Voltage

- 415 V

- Noise Level

- Low Noise Operation

- Power Rating

- 0.37 kW to 45 kW

- Efficacy

- High

- Starting Type

- Direct On Line or Star Delta

- Sealed Type

- Totally Enclosed

- Horse Power

- 0.5 HP to 60 HP

- Pressure

- Normal Atmospheric

- Ambient Temperature

- -10C to +50C

- Voltage

- 415 V

- Features

- High load capacity, compact design, maintenance free

- Cooling Method

- Surface Cooling (TEFC)

- Product Type

- Industrial Gear Motor

- Output Power

- 0.37 kW to 45 kW

- Frequency (MHz)

- 50 Hz

- Protect Feature

- IP55

- Phase

- Three Phase

- Speed

- 20 to 200 RPM

- Power

- Variable depending on model

- Color

- Grey

- Dimension (L*W*H)

- Varies by model

- Weight

- 15 kg to 350 kg

- Shaft Diameter

- 25 mm to 120 mm

- Mounting Type

- Shaft Mounted

- IP Rating

- IP55

- Lubrication

- Synthetic Oil Filled

- Efficiency

- Up to 95%

- Material

- Cast Iron / Aluminum Alloy Housing

- Vibration Level

- Low Vibration

- Output Shaft Type

- Solid Shaft

- Serviceability

- Easy Maintenance

- Mounting Position

- Horizontal / Vertical

- Service Factor

- 1.0 - 1.5

- Gear Type

- Helical

- Installation

- Easy, Plug & Play

- Duty Cycle

- S1 Continuous

- Input Method

- Motor Flange Coupling

- Insulation Class

- F

- Thermal Protection

- Integrated

Shaft Mounted Helical Geared Motor Trade Information

- Minimum Order Quantity

- 50 Units

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

About Shaft Mounted Helical Geared Motor

As one of the eminent suppliers in this domain, we are engaged in offering our clients Shaft Mounted Helical Geared Motor. This motor is used for textile machinery, winches and for material-handling equipment such as conveyors. Designed with the output shaft, which is parallel to the motor shaft, this motor is precisely engineered using the finest grade raw material with the help of high-end technology. Known for longer functional life, energy efficiency and robust construction, this Shaft Mounted Helical Geared Motor is offered at the most reasonable rates.

Features:

- Outstanding efficiency

- Greater energy savings

- Flexible mounting options

- Accessibility in slow speed operations

Specification

| Range | Power range from 0.35 KW to 70 KW, Output Speed from 2.5 to 361 RPM |

| Sizes | Available in 22 sizes |

| Type | Helical |

| Applications | Conveyors, Agitators, Pumps, Mixers, Ball Mills, Cranes, Crushers |

| Industries | Chemical, Pharma, Packaging, Food Processing, Plastic, Paper etc. |

Superior Efficiency and Versatility

Delivering up to 95% efficiency, this shaft mounted helical geared motor excels in a variety of industrial setups. Its adaptable mounting positions, variable speed range, and robust gear technology ensure seamless integration into diverse machinery, from conveyors to mixers and processing equipment. High efficacy, continuous S1 duty cycle, and versatile input methods make it a reliable choice for sustained operations.

Durable Build and Enhanced Protection

Constructed with cast iron or aluminum alloy housing, this motor resists corrosion and sustains heavy loads. Integrated thermal protection and IP55 enclosure safeguard the system against overheating and environmental hazards. With surface cooling (TEFC) and heavy duty ball or roller bearings, the geared motor guarantees prolonged service life under demanding operational conditions.

Effortless Installation and Maintenance

Engineered with plug & play features, the motor installs easily in both horizontal and vertical configurations. It offers excellent serviceability, with maintenance-free operation supported by synthetic oil lubrication and a compact, high-torque design. The solid shaft output and motor flange coupling facilitate quick connection and efficient power transfer, streamlining replacement and inspection routines.

FAQs of Shaft Mounted Helical Geared Motor:

Q: How do I install the shaft mounted helical geared motor?

A: Installation is straightforward due to its plug & play design. The motor can be mounted horizontally or vertically using a shaft mounted setup, and connections are made via a motor flange coupling. Ensure the mounting position suits your application and verify the electrical supply matches 415 V, 50 Hz, three-phase AC specifications.Q: What materials are used for the housing and how do they affect durability?

A: The motor housing is constructed from cast iron or aluminum alloy, which provides excellent resistance to corrosion and mechanical stress. Cast iron offers superior strength for heavy-duty environments, while aluminum alloy provides a lightweight alternative for easier handling and installation.Q: When is routine maintenance required for this geared motor?

A: Routine maintenance is minimal thanks to the maintenance-free design and synthetic oil lubrication. Periodic inspections of bearings and lubrication levels are recommended based on the duty cycle and operating hours, but overall the system is engineered for easy upkeep.Q: Where can this motor be used effectively?

A: This geared motor is suitable for a wide range of industrial settings, including material handling, conveyors, packaging, and processing equipment. Its high efficiency, low noise operation, and robust build make it ideal for factories, warehouses, and production facilities across India.Q: What are the benefits of using helical gears in this motor?

A: Helical gears provide smoother and quieter performance compared to other gear types, reducing vibration and noise. Their design also ensures higher torque transmission, greater load capacity, and improved efficiency, making them ideal for continuous heavy-duty operations.Q: How does the integrated thermal protection enhance safety?

A: Integrated thermal protection monitors the motors temperature in real-time and prevents overheating by shutting down if unsafe conditions are detected. This feature reduces the risk of damage, downtime, and extends the motors operational life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Geared Motors Category

Stephan Geared Motor

Minimum Order Quantity : 1 Unit

Ambient Temperature : 15C to +40C

Output Power : 0.5 HP

Voltage : 415 V

Features : Robust Construction, Low Noise, MaintenanceFree

Cooling Method : Surface Cooling

Hollow Shaft Geared Motor

Minimum Order Quantity : 1 Unit

Ambient Temperature : 20C to 50C

Output Power : 0.75 kW

Voltage : 415 V

Features : Compact Design, Maintenance Free

Cooling Method : Fan Cooled

Stephan Helical Geared Motors

Ambient Temperature : 20C to +45C

Output Power : 0.18 kW to 15 kW

Voltage : 230/400 V

Features : Robust construction, Low maintenance

Cooling Method : TEFC

Co Axial Helical Geared Motor

Minimum Order Quantity : 1 Unit

Ambient Temperature : 10C to +50C

Output Power : 0.12 kW to 45 kW

Voltage : 415 V

Features : High efficiency, Robust construction, Low noise, Maintenance free design

Cooling Method : Surface Cooling (IC411)

Send Inquiry

Send Inquiry