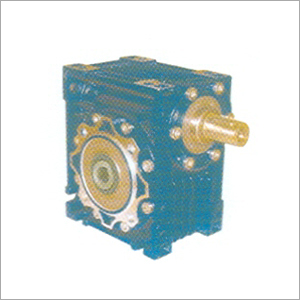

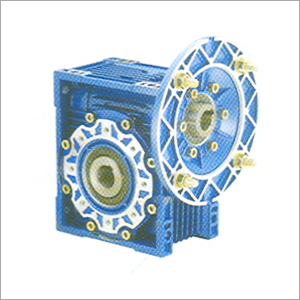

Double Reduction Worm Gearbox

Double Reduction Worm Gearbox Specification

- Gear Type

- Worm Gear

- Material

- Cast Iron

- Processing Type

- Hobbing

- Gear Tooth Profile

- Worm

- Gearing Arrangement

- Double Reduction

- Direction

- Both Direction

- Output Torque

- 200 Nm 2600 Nm

- Rated Power

- 0.5 HP 15 HP

- Input Speed

- 1440 rpm

- Output Speed

- 10 rpm 150 rpm

- Voltage

- 220 - 415 V

- Efficiency

- 70% - 78%

- Working Environment

- Industrial Usage

- Cooling Type

- Natural Cooled

- Housing Type

- One Piece Close Grain Housing

- Center Distance

- 30 mm to 100 mm

- Mounting Type

- Foot Mounted

- Output Shaft Material

- Alloy Steel

- Paint Finish

- PU Paint for Anti-Corrosion

- Noise Level

- Low Noise Operation

- Lubrication

- Oil Splash Lubrication

Double Reduction Worm Gearbox Trade Information

- Payment Terms

- Cheque

- Supply Ability

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard Packing

- Main Domestic Market

- All India

About Double Reduction Worm Gearbox

With rich industry experience and knowledge, we are engaged in offering a wide range of Double Reduction Worm Gearbox. This worm gearbox is designed and manufactured by team of adroit professionals using high quality components and latest technology in compliance with international standards at vendors end. Further, this worm gearbox is highly appreciated by our clients for its features like superior performance, simple installation, less maintenance, compact design and durable finish. Available in various technical specifications, this Double Reduction Worm Gearbox is offered at the most reasonable price to the clients.

High Durability and Protection

Thanks to the one-piece close grain cast iron housing and PU paint finish, the gearbox offers exceptional resistance against mechanical stress and corrosion, even in harsh industrial environments. This makes it suitable for long-term usage with minimal maintenance requirements.

Efficient Power Transmission

With its double reduction gearing arrangement and precision hobbing process, this worm gearbox delivers consistent efficiency between 70% to 78%. The oil splash lubrication system helps preserve gear integrity and optimizes power transfer for heavy duty cycles.

Versatile Industrial Application

Engineered for a wide range of working conditions, the gearbox supports foot mounting and both rotational directions. It operates at input speeds of 1440 rpm and offers multiple output speed and torque options, making it adaptable for various industrial machinery setups.

FAQs of Double Reduction Worm Gearbox:

Q: How does the Double Reduction Worm Gearbox ensure low noise operation in industrial environments?

A: The gearbox uses a precisely engineered worm gear tooth profile produced by hobbing, paired with oil splash lubrication and premium alloy steel output shafts. These features collectively reduce friction, vibration, and gear chatter, resulting in smooth, low-noise performance during continuous industrial use.Q: What is the benefit of using a one-piece close grain cast iron housing in this gearbox?

A: A one-piece close grain cast iron housing increases structural integrity and minimizes potential points of failure. This results in robust durability, enhanced resistance to shock loads, and reliable long-term operation even in demanding settings.Q: Where can the Double Reduction Worm Gearbox be installed in industrial settings?

A: Designed for foot mounting, the gearbox can be securely installed onto machinery bases, transmission platforms, or other stationary structures in factories and industrial plants. Its compact and sturdy design accommodates a range of machine layouts and center distances from 30 mm to 100 mm.Q: What is the lubrication process used, and how does it contribute to performance?

A: The gearbox utilizes an oil splash lubrication system, wherein oil is continuously circulated onto gears and bearings during operation. This process mitigates wear and thermal buildup, supporting consistent efficiency and extending the lifespan of moving parts.Q: How does the PU paint finish protect the gearbox in industrial environments?

A: The polyurethane (PU) paint finish provides strong anti-corrosive protection, shielding the housing from moisture, chemicals, and other corrosive agents commonly found in industrial settings. This ensures longer service life and reduces maintenance requirements.Q: When is double reduction gearing preferable in industrial applications?

A: Double reduction worm gearing is especially beneficial when significant speed reduction and high torque output are required from a compact gearbox. It is ideal for machinery such as conveyors, lifts, and heavy processing equipment where controlled motion and robust power transmission are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Boxes Category

Double Reduction Gearboxes

Minimum Order Quantity : 50 pices Units

Processing Type : Other, Precision Machined

Efficiency : Up to 95%

Material : Other, Cast Iron

Voltage : 415 V

Direction : Horizontal and Vertical

Altra Worm Gearboxes

Processing Type : Other, Precision Machined

Efficiency : Up to 90%

Material : Other, Cast Iron

Voltage : 415V AC

Direction : Both (Reversible)

Altra Gearbox

Minimum Order Quantity : 50 Units

Processing Type : Precision Casting

Efficiency : Up to 94%

Material : Other, Cast Iron

Voltage : 415V AC

Direction : Bidirectional

Altra Worm Gearbox

Processing Type : Die Casting

Efficiency : up to 90%

Material : Other, Cast Iron

Voltage : 220V/415V AC

Direction : Bidirectional

Send Inquiry

Send Inquiry